Honsberg TSG

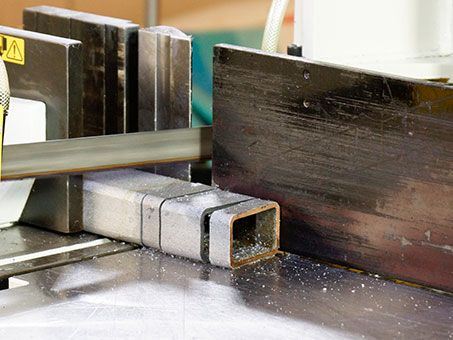

Burr on body back

PROBLEM

a) No clearance between body back and fl ange of the wheels.

b) Worn back guides.

SOLUTION

a) Adjust wheels.

b) Replace back guides.

Worn off back guides

PROBLEM

The constant rubbing along the band saw back edge has induced a brittleness. Microcracks appear. RESULT: Blade breakage.

SOLUTION

Replace back guides.

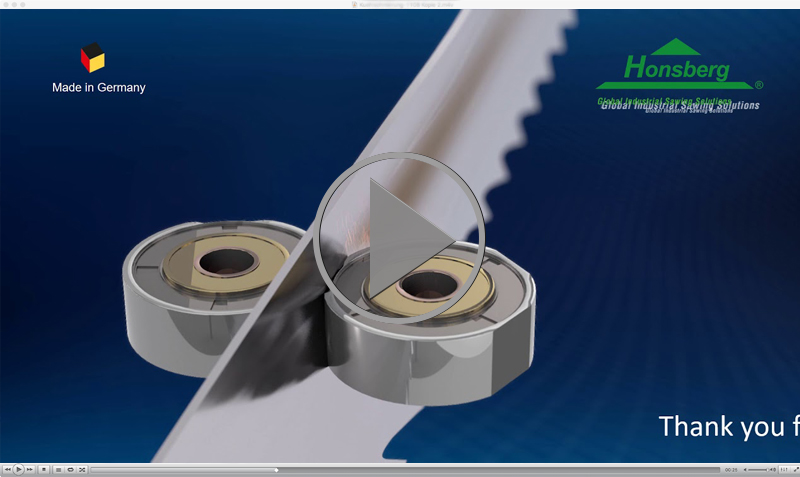

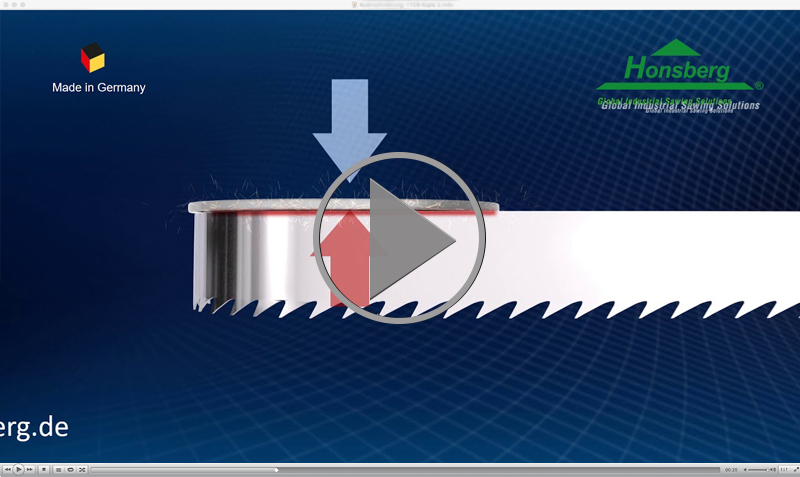

Worn damping rollers

PROBLEM

Too tight or blocked damping rollers may lead to rupture of the body.

SOLUTION

Reduce the contact pressure so the rollers can be rotated with little effort in passive state. Replace blocked damping rollers

Body crack on body back

PROBLEM

Body cracks caused by worn back guides. Leading to the back edge of the blade becoming brittle.

SOLUTION

Replace back guides.

Worn of brush

PROBLEM

Worn or incorrectly adjusted brushes are reducing the life of the saw blade.

SOLUTION

Adjust brushes regularly and replace when worn.

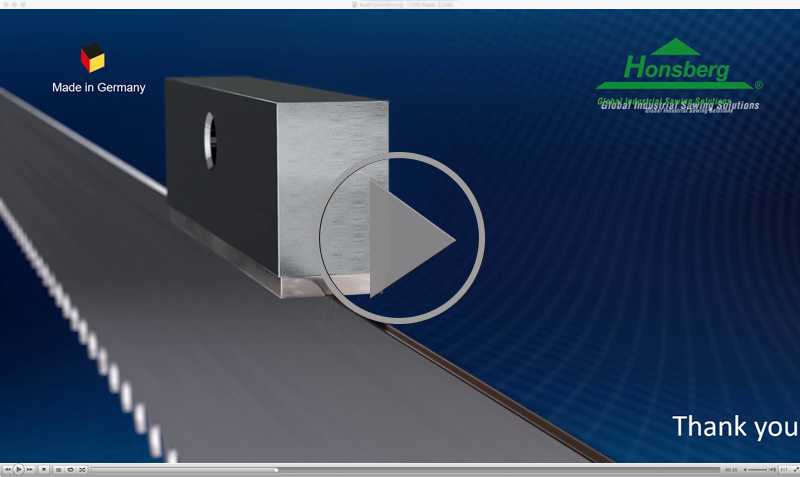

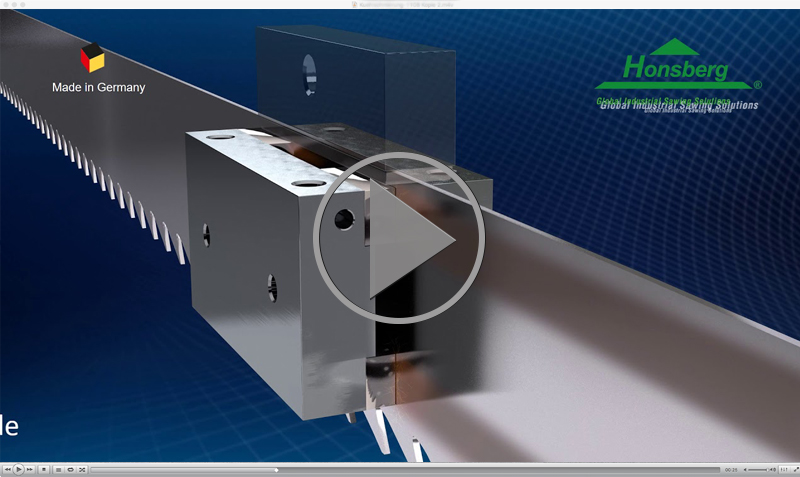

Worn side guides

PROBLEM

Too strongly adjusted or damaged side guides cause formation of microcracks and blade breakage.

SOLUTION

Reduce pressure. Clean side guides.

Tooth pitch too small

PROBLEM

The tooth gullet is too small. Chips will overfi ll the tooth gullet and lift the blade. When the chip clears the gullet, the blade will be forced back into the cutting channel resulting in a shock load on the tooth. Leading to tooth damage.

SOLUTION

Select a coarser tooth pitch.

Misaligned wheels

PROBLEM

Incorrect alignment causes burrs at the band back edge, followed by microcracks. Result: Blade breakage.

SOLUTION

Adjust wheels. Keep a clearance between band back edge and fl ange of the wheels. (Recommended clearance: 0.5 to 1.5mm).

Gullet space too small

PROBLEM

The tooth gullet is too small. To much frictional heat is generated. Result: Heavy wear and cut deviation.

SOLUTION

Select a coarser tooth pitch.

Tooth pitch too coarse

PROBLEM

Teeth have no guide in the cutting channel. Resulting in high tooth loads at the cutting point. Result: Fractures and breakages as well as microcracks in the tooth gullet.

SOLUTION

Use finer tooth pitch.

| Auf dem Knapp 42 |

| 42855 Remscheid | Germany |

| +49 2191 373-770 | ||

| +49 2191 373-799 |

| info@honsberg.de | ||

| www.honsberg.de |